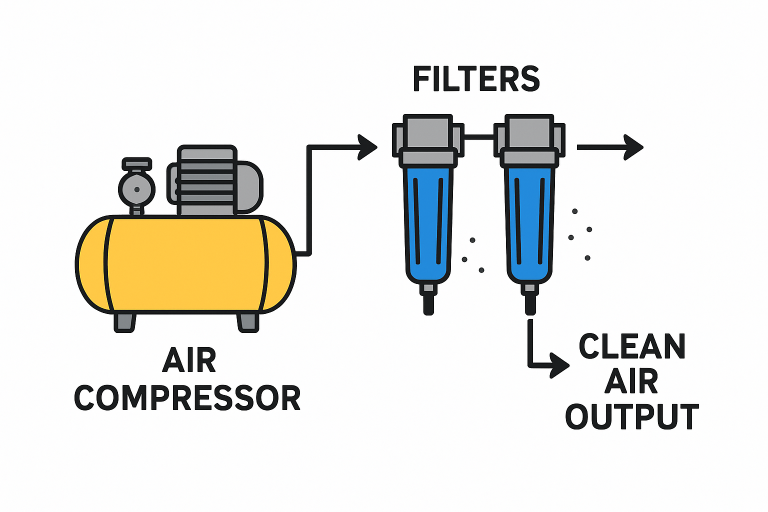

Understanding the Importance of Compressed Air Filtration

In industrial environments, compressed air acts as an invisible lifeline, powering a vast array of machinery, automation tools, and production systems. However, compressed air is only as good as its purity; contaminants such as dust, oil, and moisture can quickly degrade air quality, impacting both machinery efficiency and end-product safety. Companies worldwide rely on rigorous filtration systems to prevent downtime, equipment wear, and costly maintenance. For example, sectors such as pharmaceuticals and food processing require ultra-clean air to maintain product purity and comply with health regulations.

Mitigating the risks posed by contamination starts with proper system design and advanced solutions such as those from Airblast AFC Media Blast, which provide industrial-grade filtration and dust control. Choosing the right filtration partner is critical to safeguarding sensitive processes and extending equipment lifespan.

Maintaining optimal compressed air quality is also essential for worker safety. Moisture, oil vapor, and particulates circulating through air networks can pose health risks if they reach operator stations or open packaging areas. The presence of excess water vapor creates a breeding ground for bacteria and mold, making stringent filtration protocols a necessity in regulated settings. Even industries such as electronics and automotive manufacturing find that failing to control air contaminants drastically increases defect rates, leading to rework or product recalls. According to Industrial Safety & Hygiene News, regular testing and proactive upgrades to air filtration systems are crucial for maintaining overall operational standards.

While airborne risks are commonly addressed during initial system design, filtration requirements often evolve as facilities expand or upgrade equipment. Environmental factors, including changes in humidity, temperature, and surrounding activity, can further impact air quality. Thus, ongoing assessment is necessary to ensure standards are met for every production cycle.

Innovative Filtration Technologies Enhancing Performance

Recent years have seen significant advancements in compressed air filtration, with new materials and designs offering greater efficiency and reliability. Coalescing filters, for example, use layers of specialized media to force fine droplets of oil and water to coalesce, allowing them to be removed before these contaminants reach crucial equipment downstream. This design not only protects sensitive machinery but also reduces the load on secondary filters, improving system longevity and overall reliability. The automotive and electronics industries, known for their sensitivity to air purity, have particularly benefited from coalescing technology in assembly and painting operations.

One of the most notable innovations in this space is the shift toward filter elements engineered for low-pressure drops. These filters minimize airflow resistance in HVAC and compressed air systems, thereby reducing the load on compressors and fans. As a result, facilities can achieve the same air quality standards while using less energy, leading to significant operational savings. As detailed by Consulting-Specifying Engineer magazine, reducing pressure drop by just a few psi can translate to thousands of dollars in annual savings for a large facility.

Energy Efficiency Through Advanced Filtration

Energy Efficiency Through Advanced Filtration

Beyond protecting machinery and product quality, wise filtration choices directly influence a facility’s energy consumption. Advanced filter technologies that allow air to flow more freely can cut energy use by 30% or more in systems running multiple shifts or operating at high volume. Pressure drop, a key metric in filtration, quantifies the resistance air encounters as it passes through a filter. Lowering this resistance means compressors work less, extending their lifespan and reducing utility costs.

Energy-efficient filter designs are now a cornerstone of sustainability initiatives across the industrial sector. Data centers, hospitals, and high-tech manufacturing facilities prioritize filtration upgrades as part of broader efforts to reduce carbon footprints and comply with tightening environmental standards.

Regular Maintenance: A Cornerstone of Filtration Efficiency

Even with the best filters in place, consistent maintenance remains a cornerstone of lasting efficiency. Filters inevitably accumulate debris, increasing pressure drop and straining system performance if left unaddressed. Establishing a well-documented inspection, cleaning, and replacement interval is critical to preventing energy waste and unexpected downtime. In industries where lost production time is particularly costly, predictive maintenance systems that monitor filter health in real time are gaining widespread adoption.

Tailoring Filtration Solutions to Specific Industry Needs

No two industries require identical air quality standards. While a general manufacturing facility may focus on removing dust and oil residues, sectors such as healthcare, pharmaceuticals, and electronics require advanced sterile or ultrafine filtration solutions. Understanding the unique production risks of each application is essential for engineering effective filtration strategies. Consulting with industry-specific experts allows businesses to match solutions to their processes, environment, and regulatory requirements.

Integrating Smart Monitoring Systems

Modern filtration systems increasingly leverage sinnovativemonitoring technologies that provide real-time feedback on filter performance. Sensors can detect rising pressure drops or notify facilities managers of abnormal particulate loads, allowing immediate intervention before issues escalate. These systems facilitate precise planning for filter replacements, reduce costs, and support predictive maintenance workflows. Facilities that incorporate such intelligent monitoring consistently reduce unscheduled outages and optimize filter usage throughout their lifecycle.

Conclusion

Optimizing compressed air filtration has a far-reaching impact on equipment efficiency, product integrity, and energy savings in industrial operations. Selecting innovative filtration technologies, scheduling regular system maintenance, and aligning solutions to the specific needs of each industry empowers businesses to meet stringent quality standards while boosting sustainability. As industries continue to innovate, the importance of robust, innovative filtration solutions will only grow, shaping the future of safe, connected, and efficient manufacturing.