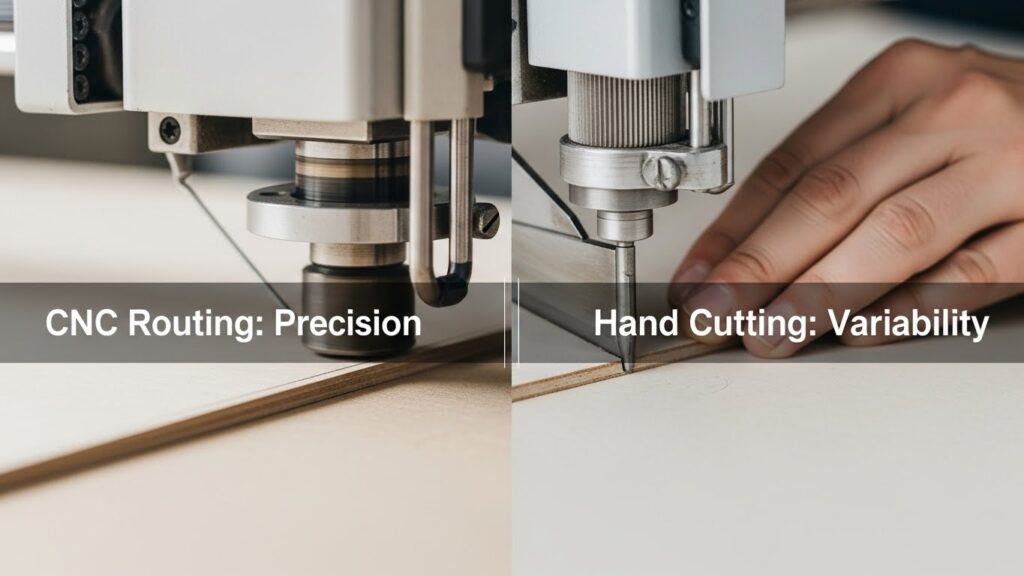

The fabrication industry has witnessed a dramatic transformation over recent decades, with computer-controlled manufacturing processes replacing traditional manual techniques. Whilst skilled craftspeople have produced impressive work through hand cutting for generations, modern CNC routing offers advantages that simply cannot be matched through manual methods.

The precision, repeatability, and efficiency of automated routing have made it the preferred choice for fabricators working with plastics, composites, and other sheet materials.

Understanding the specific benefits that CNC technology brings to the cutting process reveals why this method has become the industry standard. Let’s examine the key factors that make CNC routing superior to hand cutting.

Unmatched Precision and Accuracy

Micron-Level Tolerances

CNC routers operate with exceptional precision, consistently achieving tolerances that would be virtually impossible to maintain through hand cutting. These machines can execute cuts accurately to within hundredths of a millimetre, ensuring that components fit together perfectly every time. When projects demand exacting specifications, the automated control eliminates the variability inherent in manual techniques.

Human hands, no matter how skilled, cannot compete with the mechanical precision of computer-guided cutting heads. Even the steadiest craftsperson experiences minor tremors and fatigue that affect cutting accuracy, whilst CNC machines maintain unwavering consistency throughout production runs.

Complex Geometries Made Simple

Intricate curves, tight radii, and elaborate patterns that would challenge even experienced fabricators become straightforward with CNC routing. The technology excels at executing complex designs that would be extremely time-consuming or practically impossible to achieve by hand. Whether cutting decorative flourishes, precise mounting holes, or elaborate interlocking components, CNC routers handle complexity with ease.

Perfect Repeatability Across Production Runs

Identical Components Every Time

One of the most significant advantages of CNC routing is its ability to produce identical parts repeatedly. When manufacturing multiple components, hand cutting introduces variations between pieces, even when following templates. CNC machines eliminate this inconsistency, delivering parts that are functionally interchangeable.

This repeatability proves invaluable for projects requiring multiple identical components or for maintaining quality across separate production batches. Fabricators can confidently produce replacement parts months or years later, knowing they will match the original specifications exactly.

Reduced Material Waste

The precision of CNC routing translates directly into more efficient material usage. Whilst hand cutting often requires generous safety margins and results in more offcuts, automated routing optimises cutting paths to minimise waste. The computer can nest multiple parts efficiently on a single sheet, extracting maximum value from raw materials whilst maintaining quality.

Enhanced Productivity and Efficiency

Faster Production Times

Once programmed, CNC routers complete cuts significantly faster than manual methods, particularly for complex designs. The machine works continuously without breaks, maintaining consistent speed throughout the process. This efficiency becomes increasingly apparent on larger production runs, where the time savings compound dramatically.

Operators can also manage multiple projects simultaneously, as the CNC router works independently once the programme is initiated. This multitasking capability multiplies productivity in ways impossible with hand cutting, where the fabricator’s attention must remain focused on the cutting process.

Reduced Dependency on Specialised Skills

Whilst programming CNC machines requires expertise, operating them demands far less specialised skill than achieving comparable results through hand cutting. This accessibility allows fabrication businesses to maintain consistent quality without relying entirely on highly experienced craftspeople. The technology democratises precision fabrication, enabling newer operators to produce professional-quality work under proper supervision.

Improved Safety Standards

CNC routing significantly reduces operator exposure to cutting hazards. The automated nature of the process keeps hands and bodies safely away from moving blades and cutting zones. Whilst hand cutting requires constant physical proximity to sharp tools, potentially leading to accidents from momentary lapses in concentration, CNC operators primarily monitor the process from a safe distance.

Modern CNC routing equipment incorporates safety features such as emergency stops, protective guards, and automatic shut-offs that further minimise risk. This enhanced safety profile reduces workplace injuries whilst maintaining productivity.

Conclusion: The Clear Winner

The advantages of CNC routing over hand cutting are comprehensive and compelling. From micron-level precision and perfect repeatability to improved safety and reduced waste, automated routing delivers superior results across every meaningful metric.

Whilst traditional craftsmanship retains value in specific contexts, the technological superiority of CNC routing makes it the undisputed choice for professional fabrication work demanding consistency, accuracy, and efficiency.