Abrasive blasting is a powerful and effective method used across various industries for surface preparation, cleaning, and finishing. By propelling abrasive media at high velocity, it removes contaminants, rust, or old coatings and can create specific surface textures, offering results superior to manual methods.

Pressure Blasting: Maximum Power and Efficiency

Pressure blasting, also known as direct pressure blasting, represents the most aggressive and efficient form of abrasive blasting. This system stores both compressed air and abrasive media in a pressure vessel, creating a high-pressure mixture that delivers maximum impact force when directed at the target surface.

How Pressure Blasting Works

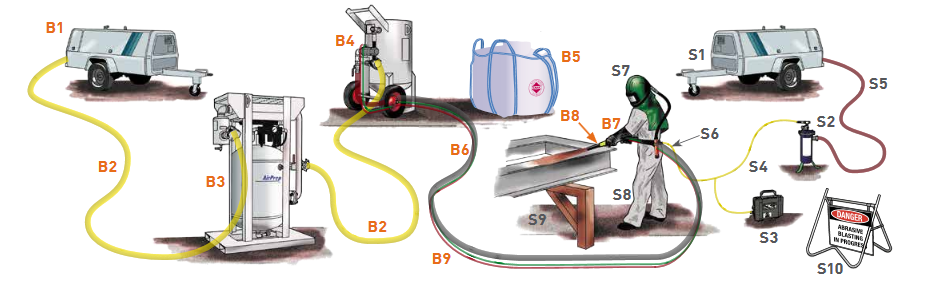

The pressure blasting process begins with abrasive media loaded into a pressure pot or blast pot. Compressed air pressurizes the entire vessel, forcing the abrasive material through a delivery hose to the blast nozzle. Because both the air and media are under pressure from the start, the system achieves higher velocities and more consistent flow rates compared to other methods.

The operator controls the blast through a remote trigger system, allowing precise application while maintaining safe distance from the high-pressure stream. Modern pressure blasting systems often include features like automated media flow controls and pressure regulation systems for enhanced consistency.

Advantages of Pressure Blasting

Pressure blasting offers several compelling benefits that make it the preferred choice for heavy-duty applications. The system delivers superior cleaning rates, often completing jobs 50-100% faster than suction-based alternatives. This efficiency translates directly into cost savings through reduced labor hours and faster project completion.

The consistent, high-pressure delivery ensures uniform surface preparation, critical for applications requiring specific profile depths or cleanliness standards. Pressure blasting also handles a wider range of abrasive media effectively, from fine glass beads to coarse steel shot, providing versatility across different surface preparation requirements.

Ideal Applications for Pressure Blasting

Large-scale industrial projects typically rely on pressure blasting for its superior productivity. Steel structure preparation, bridge maintenance, ship hull cleaning, and heavy equipment restoration all benefit from the system’s aggressive cleaning power. The method excels when removing thick coatings, heavy rust, or mill scale from large surface areas.

Construction and infrastructure projects often specify pressure blasting for preparing concrete surfaces, removing graffiti from buildings, or cleaning stone facades. The system’s ability to maintain consistent pressure over extended periods makes it ideal for continuous operation scenarios.

Suction Blasting: Versatility and Control

Suction blasting, sometimes called siphon blasting, offers a more controlled approach to surface preparation. This system draws abrasive media into the air stream through suction rather than pressurizing the media directly, resulting in lower impact forces and gentler treatment of delicate surfaces.

The Suction Blasting Process

Suction systems separate the compressed air and abrasive media until the moment of mixing. Compressed air flows through the blast gun, creating a venturi effect that draws abrasive material from an unpressurized hopper through a pickup tube. This mixing occurs at the gun itself, just before the media exits through the nozzle.

The operator maintains direct control over media flow through trigger mechanisms and adjustment valves. Many suction systems allow real-time adjustment of the air-to-media ratio, providing fine-tuned control over blast intensity and media consumption rates.

Benefits of Suction Blasting

Suction blasting provides excellent control over blast intensity, making it ideal for applications requiring delicate touch or precise material removal. The lower operating pressures reduce the risk of substrate damage, particularly important when working with thin metals, composite materials, or historically significant structures.

The system’s simpler design typically results in lower initial costs and reduced maintenance requirements compared to pressure systems. Suction blasting also offers easier media changeovers, allowing operators to switch between different abrasive types quickly for varied surface requirements within a single project.

When to Choose Suction Blasting

Smaller projects and detail work often benefit from suction blasting’s precision and control. Automotive restoration, delicate metalwork, and artwork conservation rely on the gentler approach this system provides. The method works exceptionally well for removing light rust, preparing surfaces for specialized coatings, or creating specific texture patterns.

Suction blasting proves particularly valuable in situations requiring frequent media changes or when working with expensive specialty abrasives. The system’s ability to provide consistent, controllable results makes it popular for quality-critical applications where surface specifications must be met precisely.

Wet Blasting: Clean and Contained

Wet blasting combines abrasive media with water to create a unique surface preparation method that addresses many environmental and safety concerns associated with dry blasting. This system provides effective cleaning while significantly reducing dust generation and containing the blast media for easier cleanup and disposal.

Understanding Wet Blasting Technology

Wet blasting systems mix abrasive media with water before propelling the mixture toward the target surface. The water serves multiple functions: it suppresses dust, reduces media breakdown, and provides flash rusting prevention on newly cleaned metal surfaces. Some systems add inhibitors or cleaning agents to the water for enhanced performance.

The wet mixture can be delivered through pressure-fed or suction-based systems, depending on the specific equipment design. Advanced wet blasting systems include water recycling capabilities, allowing continuous operation while minimizing water consumption and waste generation.

Advantages of Wet Blasting

Environmental benefits top the list of wet blasting advantages. The water suppresses up to 95% of dust generation, improving air quality around the work site and reducing respiratory hazards for operators. This dust control also minimizes containment requirements, often eliminating the need for extensive tarping or enclosure systems.

The wet process extends abrasive media life by reducing particle fracture and breakdown during impact. This extends media usability and reduces overall material costs. Additionally, the water helps maintain consistent temperatures on the work surface, preventing heat buildup that could affect substrate integrity.

Wet Blasting Applications

Environmental sensitivity often drives the choice of wet blasting systems. Urban projects, indoor facilities, and areas near water sources benefit from the reduced dust and containment requirements. Historic preservation projects frequently specify wet blasting to minimize environmental impact while achieving required surface preparation standards.

Marine applications particularly benefit from wet blasting’s dust control and the natural compatibility with waterfront environments. The system works well for removing marine growth, old antifouling coatings, and preparing surfaces for new protective systems on vessels, piers, and offshore structures.

Conclusion

Now that we have explored the various applications of wet blasting, it is clear that this method offers a multitude of benefits over traditional dry blasting methods. It is not only more environmentally friendly and cost-effective, but also provides better surface preparation for a wide range of materials and surfaces.