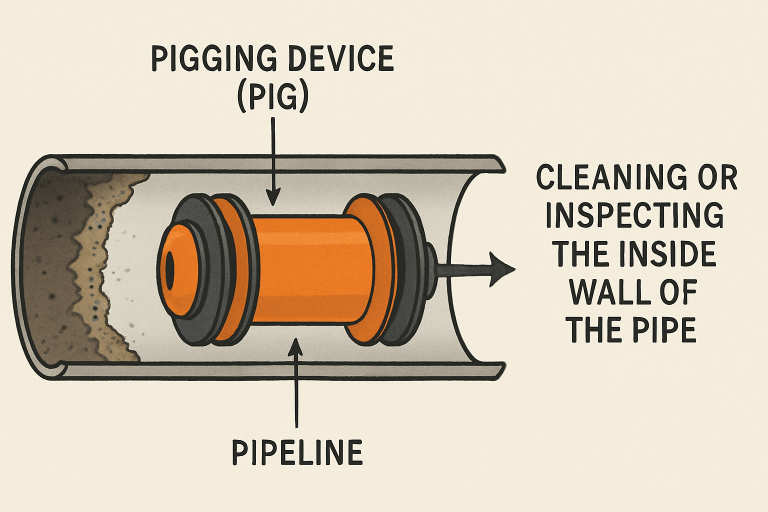

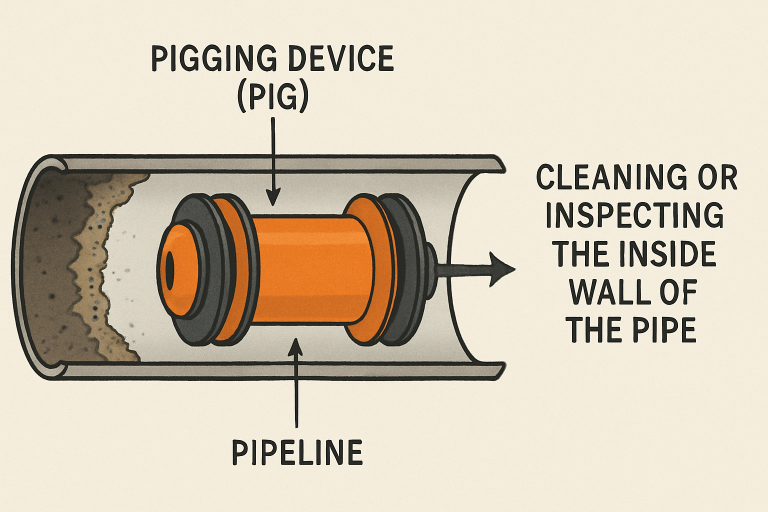

Maintaining the integrity and operational efficiency of pipelines is essential across the oil, gas, and water industries. Pigging—a specialized technique that involves the use of in-line devices known as “pigs”—enables both cleaning and inspection of pipelines without disrupting the entire system. For professionals seeking practical insight, a step-by-step guide to pipeline pigging operations can demystify the process and improve operational outcomes.

The development of sophisticated pigging tools enables pipeline operators to extend the life of their assets, reduce downtime, and ensure the safe transportation of materials. These solutions support maintenance and integrity assessments, helping companies meet regulatory and environmental challenges. As the sector evolves, operators are adopting digital and smart solutions to meet their infrastructure demands. Emerging pigging tech offers greater precision and reliability for new and legacy pipelines. Complete pigging solutions help ensure industry compliance, providing safer energy delivery while adhering to regulations. Smart strategies detect early pipeline defects, facilitating preventive action. Pigging tools now offer specialized functions: Cleaning Pigs remove debris and deposits to prevent blockages; Inspection Pigs detect issues like corrosion and defects using sensors; Intelligent Pigs combine cleaning and inspection with technologies like MFL and UT for comprehensive pipeline health assessments.

Emerging Trends in Pigging Technology

Emerging Trends in Pigging Technology

Modern pigging practices are transforming due to digital innovation, driven by several key trends. The integration of Artificial Intelligence (AI) enables sophisticated analytics that evaluate substantial inspection data to detect anomalies, facilitating predictive maintenance and risk reduction. Additionally, there is a growing demand for miniaturized and modular pigs designed for inspecting smaller or intricate “unpiggable” pipelines, allowing for adaptability to different pipeline geometries and tight bends. Furthermore, cloud-based data platforms have emerged, enabling field and office teams to share synchronized, real-time updates, thereby enhancing decision-making and streamlining workflows in maintenance projects by connecting assets, engineers, and managers across various locations.

Customized Pigging Solutions for Complex Pipelines

As pipeline networks become increasingly complex, operators demand adaptable pigging solutions, with custom pigs designed for specific project requirements. These custom-built pigs ensure precision cleaning by conforming to the internal geometry of the pipeline, thus minimizing the risk of tool bypass or entrapment. Furthermore, modern custom pigs utilize composite materials and versatile sealing discs, making them suitable for various pipeline sizes and materials, which enhances their versatility and adaptability across diverse applications. Advanced designs also incorporate sensors and monitoring technology, enabling operators to track pig performance and pipeline conditions in real-time. This integration improves operational efficiency by identifying potential issues before they escalate into costly problems. Ultimately, the combination of customization and technology supports safer, more reliable, and environmentally responsible pipeline management.

Safety Measures and Best Practices

Effective pigging ensures ongoing pipeline performance and adheres to stringent safety standards, which are vital for protecting workers and the public. It involves real-time monitoring through onboard sensors and remote telemetry, which provide live updates on pig movement and pipeline conditions, minimizing the chances of undetected tool jams or operational risks. Additionally, predictive maintenance, supported by cloud-based and AI-driven systems, enables teams to anticipate equipment deterioration or pipeline anomalies, facilitating proactive maintenance and preventing potential failures.

Environmental Considerations

Compliance with environmental regulations is crucial for pipeline operation, and smart pigging plays a significant role in sustainability efforts by decreasing emissions, unplanned discharges, and accidental spills. Regular pigging not only removes corrosive buildup but also prevents leaks that could result in expensive ecological damage. Additionally, it helps ensure that pipelines adhere to stringent industry and environmental standards, thereby minimizing environmental impact and enabling companies to avoid fines and damage to their reputation. By maintaining pipeline integrity, operators also promote safer working conditions and protect surrounding communities. Furthermore, consistent use of smart pigging technology demonstrates a commitment to long-term environmental stewardship and responsible resource management.

Conclusion

Pigging remains an indispensable tool in the ongoing effort to maintain and optimize vital pipeline infrastructure. Technological advancements, ranging from intelligent inspection tools to AI-driven analytics and custom pigging solutions, are elevating the standards for pipeline safety, efficiency, and environmental stewardship. By leveraging the latest innovations and adhering to robust safety practices, operators can extend pipeline lifespans and deliver safer, more sustainable transportation of resources well into the future.