The food and beverage manufacturing sector is undergoing a radical transformation, spurred by the rising demand for quality, consistency, and operational agility. Embracing the power of data is no longer optional—manufacturers are harnessing digitally enabled production models to outpace competitors and meet evolving consumer expectations. Central to this transformation is the adoption of factory software for food and beverage companies, enabling real-time monitoring, smart analysis, and optimized efficiency at every stage of production. By integrating data-driven strategies and innovative technologies, companies can maximize outputs, reduce inefficiencies, and foster sustainable growth. These advancements let manufacturers track trends in consumer demand, respond faster to quality issues, and adapt proactively to new regulations and market developments, fundamentally reshaping how food and beverage plants operate.

Embracing Digital Transformation

Digital transformation is ushering in a new era of intelligence for food and beverage manufacturers by embedding cutting-edge solutions such as the Industrial Internet of Things (IIoT), Artificial Intelligence (AI), and advanced Manufacturing Execution Systems (MES). These technologies empower operations teams with real-time visibility, unlocking granular process control and unmatched scalability. In recent years, the industry has seen a dramatic uptick in digital adoption: over three-quarters of food producers are implementing digital strategies to drive efficiency and minimize waste, according to a Digital Information World report. These innovations also enhance food safety compliance by ensuring traceability across every production stage. As a result, manufacturers can respond faster to market demands while maintaining consistent quality and sustainability.

Leveraging Predictive Analytics

Predictive analytics transforms reactive operations into proactive strategies. By mining historical and real-time production data, manufacturers can forecast equipment maintenance needs and predict potential quality deviations before they cascade into larger problems. This data-driven precision has tangible benefits: research shows predictive maintenance models can raise product yield from 78.38% to as much as 89.62%, validating the substantial ROI for plants leveraging analytics-powered production.

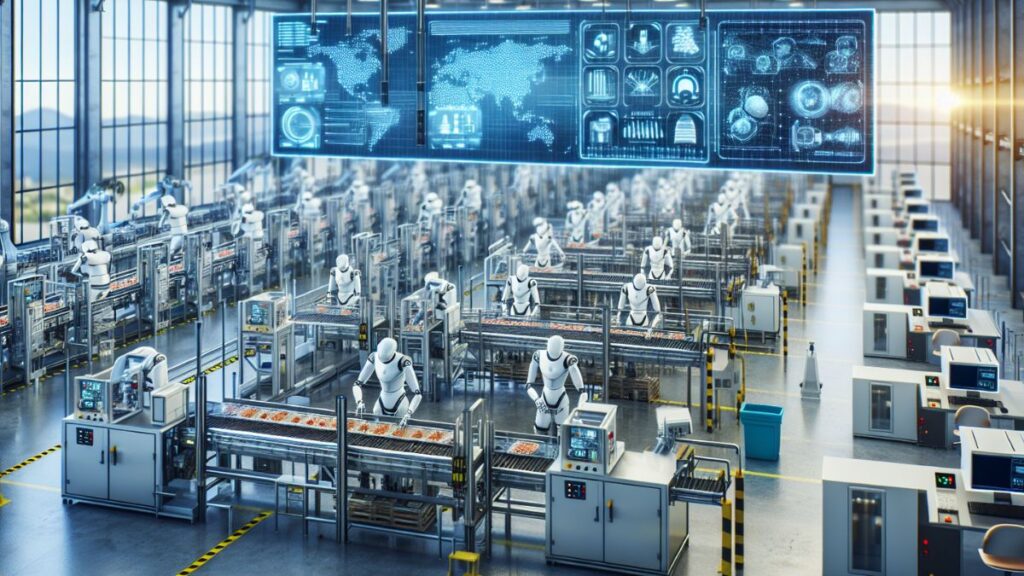

Implementing Automation and Robotics

The integration of automation and robotics is a defining factor for modern food and beverage facilities. Automated systems reliably handle repetitive, demanding tasks—such as sorting, inspecting, and packaging—minimizing human error and improving workplace safety. Robotics, coupled with advanced vision and control software, enable precise quality control and optimize throughput. This helps businesses maintain high standards while addressing labor shortages and rising consumer expectations. With automation and robotics at the heart of operations, manufacturers can redirect human ingenuity to higher-value work such as process optimization and continuous improvement. This not only accelerates output but also integrates seamlessly with digital platforms for holistic process oversight.

Enhancing Supply Chain Transparency

Modern supply chains are increasingly complex, requiring robust tracking systems to ensure traceability, food safety, and swift compliance with regulatory demands. Blockchain and digital ledger technologies deliver end-to-end visibility over raw materials, inventory, and logistics, simplifying recall management and boosting consumer trust. Recent industry reports highlight that more than half of food manufacturers are investing in blockchain to fortify their supply chain transparency.

Adopting Digital Twin Technology

Digital twins—virtual mirrors of physical production environments—empower manufacturers to simulate, monitor, and refine their processes in real time. By modeling various scenarios, identifying production bottlenecks, and testing improvements before actual implementation, businesses reduce risk and respond rapidly to changing market conditions. Notably, a dairy company leveraged digital twin technology to generate an additional $98 million in revenue during the COVID-19 lockdown, emphasizing the transformative value of digital simulation in navigating industry disruption.

Fostering a Culture of Continuous Improvement

High-performing food and beverage plants are distinguished by their commitment to continuous improvement. Data-driven performance monitoring—bolstered by visual analytics—empowers teams to identify inefficiencies, test hypotheses, and track the impact of changes over time. This iterative approach cultivates an environment where innovation thrives and operational resilience is always evolving. Visual analytics tools now enable side-by-side comparisons of production plans, providing decision-makers with actionable insights that drive efficiency gains.

Investing in Employee Training

The digital revolution in manufacturing has amplified the need for a skilled workforce capable of collecting, interpreting, and acting on production insights. Dedicated training programs focused on data literacy, business intelligence, and integrated systems ensure staff members are equipped to drive digital transformation forward. When employees become adept in digital tools and analytics, companies experience smoother transitions, higher morale, and greater returns on their technology investments.

Conclusion

For food and beverage manufacturers, the path to operational excellence is paved with data-driven production solutions. From adopting factory software for food and beverage companies and implementing predictive analytics to leveraging automation and digital twins, these strategies deliver next-level performance, transparency, and agility. Coupled with a continuous improvement mindset and consistent employee training, manufacturers can remain competitive—adapting nimbly to marketplace shifts and exceeding consumer expectations. Future-ready food and beverage plants are, at their core, data-driven.