A color sorter machine uses advanced optical technology to detect and separate products based on color, shape, and material. Industries value this automation because it improves accuracy, reduces waste, and increases productivity. Market demand continues to rise, with the global optical sorter machine market projected to reach over USD 6 billion by 2033. RaymanTech Optical Sorting Systems lead this field by offering precise, efficient solutions professionals trust for quality control.

What Is a Color Sorter Machine?

Definition and Function

A color sorter machine, sometimes called a color sorting machine, sorts objects by color using optical sensors or cameras. Industries such as food processing, recycling, and agriculture rely on this device to separate and classify materials based on their colors. The machine plays a vital role in quality control. It inspects raw materials for defects and contaminants, removing impurities to ensure high-quality products. Automation with a color sorter machine eliminates the inefficiencies of manual sorting and increases productivity.

Color sorter machines help companies deliver safer and more consistent products to consumers.

Color sorting technology has transformed how industries handle bulk materials. By using advanced sensors and cameras, these machines detect even the smallest differences in color, shape, or material. Modern color sorters can process large volumes quickly, making them essential in today’s fast-paced production environments.

How It Works

A color sorter machine uses several key components to perform its tasks. These parts work together to inspect, analyze, and sort materials efficiently.

- Swinging feeding hopper

- Vibrating feeder

- Chute slide

- Light source

- Background plate

- CCD detection lens

- Good product tank

- First defective product tank

- Second defective product tank

- Jet nozzle

- Air compressor

- Air purifier

- Filter

- Cleaning system (cylinders and glass wipers)

- Swinging discharge system

- Operating system (large screen color touch operation platform)

The sorting process begins at the infeed stage. Products enter the machine through conveyor belts or feeders. High-speed cameras and sensors capture images of the materials, analyzing characteristics like color and size. AI algorithms process the data and classify materials based on preset sorting criteria. The machine then ejects unqualified products using mechanical arms or air jets.

- The optical sorting machine scans items on a conveyor belt using high-resolution cameras.

- It records key details and analyzes them in real time to detect variations from quality standards.

- Items that do not meet the criteria are marked for rejection and ejected quickly to avoid slowing down production.

- The system maintains high speed and accuracy, ensuring only the best products move forward.

Modern color sorters use these steps to deliver precise results. The combination of advanced imaging, AI, and mechanical sorting allows industries to achieve high levels of purity and efficiency.

Features of Color Sorter Machine

Key Technologies and Capabilities

Modern color sorting machines rely on advanced technologies to deliver a high level of precision and quality. Manufacturers integrate artificial intelligence, multispectral detection, and sophisticated imaging systems to improve sorting accuracy. These machines use high-resolution cameras and AI algorithms to capture detailed images and analyze products in real time. This process allows the color sorter machine to identify subtle differences in color, shape, and material, which leads to better sorting results.

| Technology Type | Description |

| AI-powered sorting | Utilizes artificial intelligence to enhance sorting accuracy and speed. |

| Advanced imaging | Employs sophisticated imaging technology for precise color detection. |

| Multispectral detection | Combines various wavelengths to identify subtle color variations and impurities. |

Color sorting machines reduce product rework and waste by up to 15%. They also improve overall production efficiency and enhance sorting accuracy and speed. AI systems detect tiny color variations and remove mold or foreign objects, which improves product quality. Deep learning algorithms help machines adapt to new materials and colors. Facilities report labor cost reductions of up to 59% due to automation.

RaymanTech Optical Sorting Systems Overview

RaymanTech Optical Sorting Systems stand out in the market for their multi-perspective detection, ultra-high-definition imaging, and hygienic design. These features support a high level of precision and quality in sorting applications.

| Feature | RaymanTech Optical Sorting Systems | Competitors (e.g., Key Technology) |

| Multi-Perspective Detection | Up to five synchronized angles | Single-view systems |

| Ultra-High-Definition Imaging | Detects microscopic flaws | Standard optics |

| AI-Powered Recognition | Self-training machine learning | Predefined rules only |

| Hygienic Design | Waterproof, dustproof, easy to clean | Varies, often less compliant |

RaymanTech offers several popular models, each designed for specific sorting needs:

| Model | Features | Advantages |

| ROS-600DBLS | AI-powered sorting, ultra-high definition camera, IP66 protection | Accurate detection of contaminants, reliable in challenging environments, easy maintenance |

| ROS-900DBLS | Belt speed: 96m/min, quick-release mechanism | Reduces damage to fragile products, suitable for a wide range of applications |

| ROS-1200DBLS | Easily removes tiny impurities, reliable operation in wet environments | Effectively captures tiny impurities, ensures reliable performance in high-dust environments |

Industry Applications of Color Sorter Machine

Food Processing and Agriculture

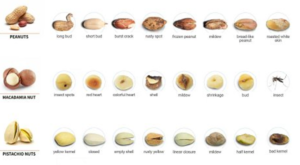

Color sorter machines play a vital role in food processing and agriculture. These machines help producers deliver safe, high-quality rice, beans, and other crops to the market. In seed and grain processing, color sorters detect and remove discolored grains, stones, glass, and other harmful impurities. This process improves quality and reduces waste. Producers meet strict market demands for premium food by using advanced sorting technology.

| Feature | Description |

| Defect Detection | Accurately identifies and removes discolored grains, stones, glass, and other harmful impurities. |

| Quality Enhancement | Improves grain quality and reduces waste. |

| Market Demand Compliance | Helps producers meet the growing market demands for safe and premium food. |

Color sorter machines also identify issues such as overripeness, underripeness, disease, insect damage, bird or rodent damage, bruising, dirt, fungus, or mold. These machines ensure only the best rice and beans reach consumers. RaymanTech Optical Sorting Systems offer specialized models for rice, beans, and nuts. The AI Medium Speed Optical Sorter handles fragile, moisture-rich, and oily products, making it ideal for fresh and frozen vegetables. The AI Multi View Optical Sorter provides nearly 360° coverage, detecting micro-defects in rice and beans. RaymanTech’s technology supports fast and efficient sorting, which boosts production and quality assurance.

RaymanTech’s solutions help food processors achieve high accuracy and maintain strict hygiene standards, ensuring consistent product quality.