In precision-driven industrial environments, material selection is a critical engineering decision. Performance requirements such as dimensional stability, vibration control, durability, and resistance to environmental stress often outweigh considerations of weight or appearance. For this reason, lead remains specified in applications where reliability and predictable behavior are essential.

Even as alternative materials evolve, engineered lead components remain a trusted solution across precision machining, architectural detailing, and specialized manufacturing environments where tolerances are tight and performance margins are narrow.

Material Characteristics That Sustain Lead’s Industrial Relevance

Material Characteristics That Sustain Lead’s Industrial Relevance

Lead offers a unique combination of physical properties that remain difficult to replicate in a single material. These characteristics directly contribute to its continued use in demanding industrial applications:

- High density supporting effective vibration and sound attenuation

- Exceptional malleability allows for precise forming without fracture

- Natural resistance to corrosion and moisture exposure

- Stable behavior under mechanical and environmental stress

Together, these properties make lead especially suitable for long-term use in environments where consistency and durability are critical.

Precision Machining and Dimensional Accuracy

Manufacturing systems that depend on strict tolerances require materials that behave consistently during machining. Precision CNC Lead components are produced to exact specifications, supporting repeatable accuracy across production cycles.

These components are commonly used in:

- Counterbalance and weight-critical assemblies

- Vibration-sensitive mechanical systems

- Precision fixtures and industrial tooling

- Applications requiring controlled mass distribution

Lead’s predictable machinability allows engineers to maintain dimensional control without introducing variability into complex systems.

Flexible Lead Forms for Structural and Industrial Integration

Adaptability is a critical requirement in both construction and industrial design. A lead sheet enables conforming to complex geometries while maintaining structural integrity over time.

Due to its flexibility and durability, sheet lead performs reliably in environments exposed to movement, vibration, and long-term environmental conditions. Professionally manufactured Lead Sheets are widely specified for architectural detailing, industrial linings, acoustic control systems, and precision-fabricated components.

Edge Protection and Termination Precision

Structural interfaces and exposed edges require materials that maintain dimensional stability over extended periods. Lead TCaps are engineered to provide consistent coverage while preserving material integrity in demanding conditions.

They are commonly applied in:

- Architectural finishing details

- Structural edge protection systems

- Interfaces exposed to environmental stress

- Applications requiring long-term reliability

Precision-formed lead profiles help ensure consistent performance without compromising surrounding materials.

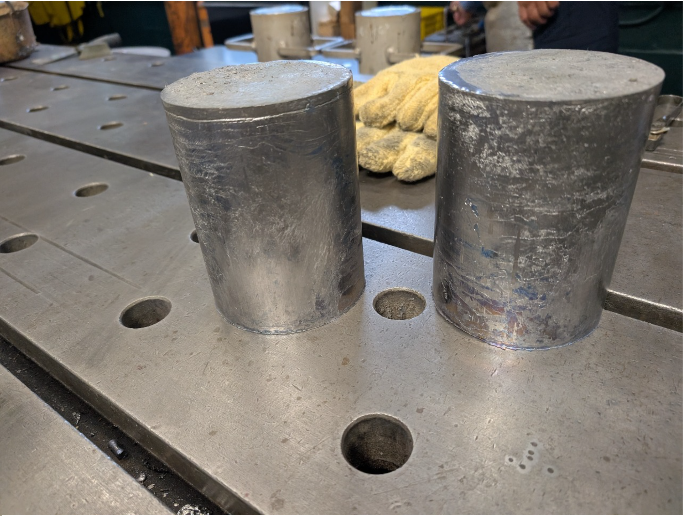

Custom Cast Lead for Specialized Industrial Requirements

Certain applications require custom geometries that cannot be achieved through standard profiles or machining alone. Lead Castings enable the production of components with controlled density, exact weight, and application-specific shapes.

Custom cast lead components are frequently used in:

- Industrial tooling and mold systems

- Counterweight and balance assemblies

- Shielding and containment solutions

- Specialized manufacturing environments

Controlled casting processes ensure uniformity and repeatable performance in highly demanding use cases.

Manufacturing Precision Defines Long-Term Performance

While lead’s inherent properties provide significant advantages, long-term performance ultimately depends on manufacturing precision. Dimensional accuracy, material consistency, and application-specific engineering are essential to ensuring reliable outcomes.

High-quality lead manufacturing prioritizes:

- Tight tolerance control

- Consistent production processes

- Application-driven design considerations

- Long-term performance reliability

This engineering-first approach allows lead components to continue meeting modern industrial requirements.

Conclusion

Engineered lead components remain integral to precision manufacturing, architectural detailing, and industrial design, where performance cannot be compromised. Their unique physical characteristics, combined with controlled manufacturing processes, make lead a dependable material for specialized applications.

As industrial demands continue to evolve, precision-engineered lead solutions will remain a foundational choice for environments driven by accuracy, durability, and reliability.