Introduction

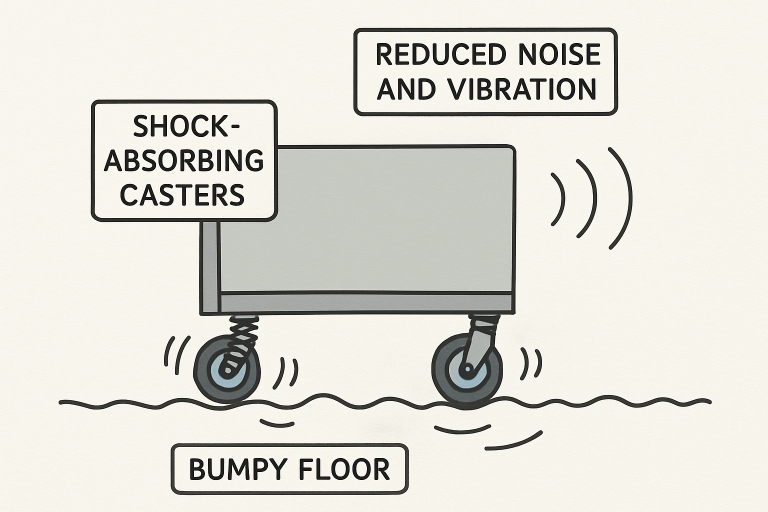

Industrial workplaces expose employees and equipment to challenges such as excessive noise and persistent vibrations, which can affect both productivity and health. A practical and effective solution to reducing these issues is the use of shock absorbing casters. These highly engineered wheels are designed to cushion blows, absorb noise, and offer a smoother experience for both operators and equipment.

By integrating these advanced casters, businesses can create more ergonomic environments. This improves worker comfort and safety, while also supporting compliance with occupational health guidelines on noise exposure. Shock-absorbing casters are becoming an essential upgrade for organizations striving to modernize and optimize their facilities.

Excessive noise doesn’t just cause physical discomfort; it increases stress levels, impairs concentration, and slows productivity. In many cases, it also accelerates operator fatigue, a leading cause of errors and job-related injuries. Addressing these sources of workplace disruption starts on the ground—with the casters beneath your carts, dollies, and equipment.

Incorporating innovative caster technology can have tangible results for daily workflow and operator morale. Investments in shock-absorbing casters can even contribute to improved equipment longevity, reducing losses associated with breakdowns and repairs caused by uncontrolled vibrations.

Understanding Shock-Absorbing Casters

Shock-absorbing casters are specifically designed to dampen unwanted energy generated by rough floor surfaces or sudden load impacts. They typically employ spring-loaded mechanisms or utilize specialized composites to provide absorption, minimizing vibration transfer. Instead of allowing every jolt to travel upward into equipment and operator handles, these casters contain movement that is directed to the floor contact area.

The technology behind these casters means less energy is wasted, fewer interruptions to workflow occur, and operators remain comfortable for longer periods of use. In environments where smooth transportation of materials is necessary—and where vibrations could harm electronics or precision items—the presence of shock-absorbing casters helps maintain reliability and efficiency.

To better understand their impact, it is helpful to examine how the mechanics of vibration absorption protect both the equipment and the people using it. According to OSHA guidelines on workplace noise, even modest reductions in decibel levels can greatly affect both health outcomes and productivity. Effective caster design ensures that mitigating noise and shock starts at floor level.

Benefits of Using Shock-Absorbing Casters

- Noise Reduction: As motion is transmitted through cart wheels, standard casters can amplify rattling and banging across facility floors. Shock-absorbing models contain these vibrations, helping organizations comply with local and federal noise limits. Studies indicate potential reductions of up to 15 dBA in certain environments.

- Enhanced Operator Comfort: Vibrations not only travel to equipment, but can be felt by operators through handles and platforms. Repeated exposure increases fatigue and risk for repetitive strain injuries. Shock-absorbing casters ensure that laborers remain comfortable and alert throughout shifts.

- Protection of Sensitive Equipment: For businesses handling electronics, precision instruments, or delicate goods, shock absorption prevents costly equipment failures and damage. Reduced impact ensures longer service life for everything from hospital beds to automated guided vehicles on production lines.

Applications in Various Industries

Shock-absorbing casters are implemented across diverse sectors due to their adaptability and performance. In manufacturing, they are used with heavy rolling carts that move components around shop floors. In hospitals, these casters are a must on medical carts and hospital beds, where noise and sudden movement could disrupt patient care. Similarly, logistics companies utilize them for the safe and efficient transportation of valuable goods.

In healthcare, for instance, the importance of quietness and stability cannot be overstated. Medical carts and beds equipped with these casters provide a calm environment, which is crucial for patient recovery.

Additionally, warehouses and fulfillment centers witness substantial gains when these casters are fitted to transport trolleys and rack systems. With quieter and smoother operations, worker communication improves, and workplace stress is reduced.

Key Features to Consider

- Load Capacity: Casters must be selected based on the weight they need to carry to avoid premature wear or failure.

- Wheel Material: Polyurethane and rubber are popular choices for minimizing noise and enhancing durability.

- Spring Mechanism: The effectiveness of shock absorption is greatly influenced by the sophistication and adjustability of the spring mechanism within the caster.

- Floor Compatibility: Matching caster design to your flooring type ensures longevity and optimal vibration damping.

It is also wise to consult trusted industry resources to confirm which models are recommended for specialized applications.

Implementing Shock-Absorbing Casters

- Conduct a needs assessment by evaluating the environment and equipment to be mobilized.

- Select casters that match your required specifications, ensuring compatibility with both your load and the type of flooring.

- Develop a maintenance schedule to routinely check functionality, lubricate moving parts, and replace worn casters for consistent performance.

Integrating shock-absorbing casters as part of broader workplace safety and comfort initiatives is a proven way to reduce absenteeism and increase staff satisfaction.

Final Thoughts

Implementing shock-absorbing casters provides tangible benefits, including noise reduction, improved operator comfort, and extended equipment longevity. Their adaptability across industries underscores their value as a cornerstone of workplace safety and productivity strategies. By selecting the right caster solutions and maintaining them properly, organizations can make significant strides in enhancing worker safety, performance, and satisfaction.