Silicone has become a highly versatile material in modern manufacturing due to its durability, flexibility, and resistance to extreme temperatures. Among the various processes used to shape silicone products, LSR molding (Liquid Silicone Rubber molding) stands out as one of the most effective. From medical devices to consumer electronics, this technique is widely used for producing high-quality, precision components.

What is LSR Molding?

Liquid Silicone Rubber (LSR) molding is a manufacturing process in which liquid silicone is injected into a mold to produce flexible, durable, and heat-resistant components. Unlike traditional rubber molding methods, LSR molding is fully automated, ensuring precision and repeatability.

How Silicone Rubber Injection Molding Works

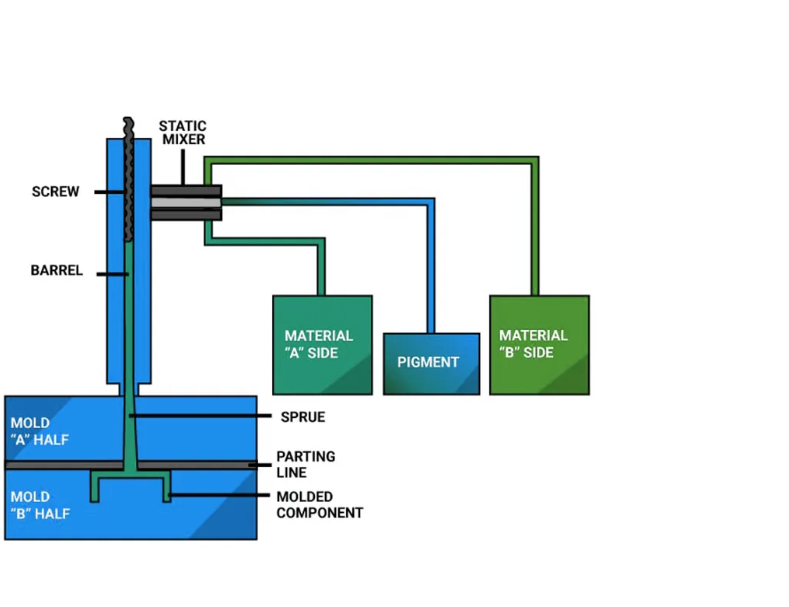

Silicone rubber injection molding is a multi-step process that combines advanced machinery with high-quality liquid silicone materials. The steps include:

1. Material Preparation

The process begins by mixing two liquid components (A and B) that include the base silicone and a curing agent. Pigments or additives may also be added.

2. Injection into the Mold

The liquid silicone mixture is injected into a heated mold cavity under high pressure.

3. Curing Process

Once inside the mold, the silicone cures quickly due to the heat, solidifying into the desired shape.

4. Demolding

The finished part is ejected from the mold and is ready for post-processing if needed.

Advantages of LSR Molding

LSR molding is popular because it offers several advantages over other molding techniques:

- High precision: Ideal for complex geometries.

- Durability: Resistant to heat, chemicals, and UV radiation.

- Consistency: Automated production ensures uniform parts.

- Flexibility: Can produce soft-touch components.

- Cost-efficiency: Suitable for both small and large production runs.

Key Applications of Silicone Rubber Injection Molding

Silicone rubber injection molding has a wide range of applications across industries:

Medical Industry

Used in catheters, pacifier nipples, and medical seals due to biocompatibility.

Automotive Industry

Applied in seals, gaskets, and connectors resistant to fuel and extreme temperatures.

Consumer Products

Popular for kitchenware, baby products, and wearables.

Electronics

Used in waterproof seals, keypads, and protective covers.

Materials Used in LSR Molding

Liquid silicone rubber comes in several formulations designed for specific applications:

- Medical-grade LSR – Non-toxic and biocompatible.

- High-transparency LSR – Used for optics and lighting products.

- Self-lubricating LSR – Ideal for seals and gaskets.

- Flame-retardant LSR – Used in electronics and automotive.

Comparing LSR Molding with Other Rubber Molding Processes

To better understand its advantages, it’s worth comparing LSR molding with other methods:

LSR vs Compression Molding

- LSR: Automated, faster cycle times, better for high volume.

- Compression molding: Manual, slower, suitable for low-volume production.

LSR vs Transfer Molding

- LSR: Cleaner, more precise, less waste.

- Transfer molding: Good for medium-volume production but less accurate.

Challenges in LSR Molding

Although highly efficient, LSR molding has its challenges:

- High initial cost for molds and machinery.

- Specialized expertise needed for mold design.

- Material waste during trial runs.

These challenges can be overcome with proper design optimization and automation.

Design Considerations for Silicone Rubber Injection Molding

When designing parts for LSR molding, engineers must keep in mind:

- Wall thickness: Uniform walls ensure proper curing.

- Undercuts: Should be minimized to ease demolding.

- Venting: Essential for removing trapped air.

- Shrinkage allowance: Must be calculated into the design.

Quality Control in LSR Molding

To ensure consistency, manufacturers implement strict quality measures:

- Dimensional inspections using precision measuring tools.

- Material testing for hardness, tensile strength, and heat resistance.

- Automated inspection systems for large-scale production.

Future Trends in Silicone Rubber Injection Molding

The future of LSR molding looks promising, with several innovations on the horizon:

- Overmolding with LSR for multi-material components.

- Micro-molding for tiny medical and electronic parts.

- Sustainable silicone materials with reduced environmental impact.

- Industry 4.0 integration for real-time monitoring and optimization.

Conclusion

LSR molding, or silicone rubber injection molding, has revolutionized the way manufacturers produce durable, precise, and high-performance silicone parts. With applications spanning from healthcare to electronics, it offers unmatched reliability and versatility.

By combining automation, material innovation, and advanced design techniques, LSR molding continues to evolve and shape the future of modern manufacturing.