What Is Diamond Wire Sawing?

Diamond wire sawing has rapidly become an essential tool for cutting through reinforced concrete, steel, and masonry, especially for large-scale construction and demolition projects. Utilizing a wire embedded with industrial-grade diamonds, this technique creates clean, precise cuts while significantly reducing the noise, dust, and vibration found with traditional cutting methods. For those looking to dive deeper into this process’s principles and various uses, Read more here about its wide-reaching applications and adaptability.

Unlike impact or blade saws that often cause stress on a structure, diamond wire sawing uses continuous friction to slice through even the thickest materials with ease. This ability to cut intricately and precisely is particularly useful for delicate constructions. Access is difficult, or downtime is costly. Interest in this technique is steadily rising as the industry looks to solutions that balance efficiency, safety, and sustainability on the largest jobs.

Delivering Efficiency in Large-Scale Construction

The scale of modern infrastructure projects puts tremendous pressure on contractors to meet deadlines while ensuring high standards. Diamond wire sawing allows workers to cut through sizable structural elements—like bridge piers, dam walls, or reinforced slabs—quickly and with less manual intervention. Thanks to the low levels of noise and vibration, multiple teams can often work simultaneously, streamlining coordination across trades on crowded sites. This boost to productivity is a key reason why more project managers have turned to diamond wire sawing for challenging assignments.

How Technology Boosts Productivity

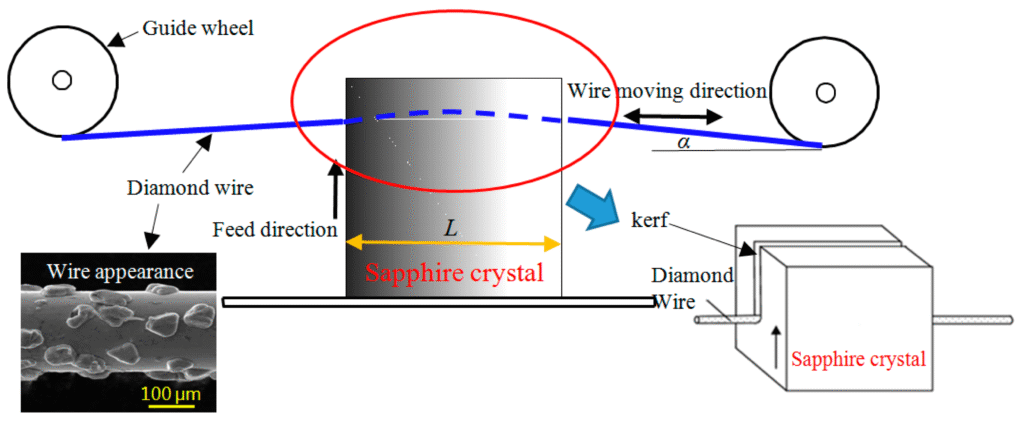

The mechanics of diamond wire sawing are built for speed. The combination of rapid wire movement and abrasive diamond beads makes it possible to penetrate materials that would stall conventional equipment. Water or oil typically cools the system and manages debris, reducing tool wear and the frequency of blade replacements. For example, industry research featured in published reports underscores the role of wire sawing in transforming how civil engineers approach complex demolition and retrofits.

The result is faster completion of cutting tasks, fewer interruptions for tool changes, and less risk of structural damage. This directly impacts project timelines, giving construction teams more control over their scheduling while accommodating unpredictable challenges like bad weather or shifting project scopes.

Cost-Saving Advantages on Big Jobs

Budget overruns are common in large-scale construction, but diamond wire sawing delivers several cost-saving benefits. Since the system cuts precisely, there’s less material waste and little need for secondary finishing. The method’s minimal vibration reduces collateral damage to surrounding structures, saving on unforeseen repair costs. Additionally, this advanced approach limits labor and energy demands, translating into measurable reductions in direct and indirect expenses. As industry professionals point out, tools that enhance efficiency without sacrificing quality are vital in keeping large-scale developments within budget.

Environmental and Safety Benefits

Sustainability and worker safety are now top priorities in construction planning. Diamond wire sawing generates very little dust and considerably less noise, contributing to a safer, healthier job site for everyone involved. These traits also make it easier to meet local environmental and occupational safety requirements, which are especially stringent in urban areas or near sensitive sites. The reduced airborne silica and debris support long-term worker health and help garner community support for extensive construction activities.

Future Trends in Demolition and Concrete Cutting

Innovation in diamond wire sawing is shaping the future of large-scale construction. Modern machines now include smart automation, remote controls, and adaptive tensioning, further streamlining operations. Tool materials and system designs evolve, leading to longer-lasting wires and greater cutting versatility. As client demands for speed and environmental stewardship increase, cutting techniques like this are expected to play an even bigger role in shaping the built environment.

Steps To Maximize Value With Diamond Wire Sawing

Proper planning is essential before any wire sawing operation begins to ensure efficiency and safety.

- Evaluate the scope and scale of the project to determine the right wire sawing system and setup.

- Coordinate with site managers to optimize equipment placement for access and cut quality.

- Choose wire compositions and pulley alignments tailored to each material and structural challenge.

- Implement continuous training for operators to stay updated on best practices and jobsite safety protocols.

Ongoing performance reviews and equipment checks can further enhance precision and reduce downtime.